Skype: +86 193 3849 2153

EMAIL: Nancy@jnhgbf.com

If you are interested in our products, Please get in contact with us .

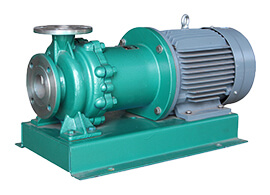

E-mail: Nancy@jnhgbf.com Chat Line Send InquiryCorrosion-resistant and wear-resistant mortar pump, also known as corrosion-resistant and wear-resistant pump, is a pump that can adapt to various working conditions, such as conveying acid, alkaline liquid or slurry; various corrosive ore pulps in the smelting industry ; Various types of dilute acids in the sulfuric acid industry; various types of sewage in the environmental protection industry. The pump is both corrosion-resistant and wear-resistant, and is widely used. In chemical manufacturing, some substances are often corrosive, so anti-corrosion machinery is widely used. The following are some aspects of the application of anti-corrosion and wear-resistant pumps.

First, pay attention to maintaining the stability of the application of the anti-corrosion and wear-resistant pump, so that it has a stable volumetric efficiency, to facilitate the operation of the anti-corrosion and wear-resistant pump itself and the stability of the downstream spinning quality;

Second, always check the temperature of the heat medium jacket, the heat medium temperature of the main body and the front and back covers should be kept the same;

3. The inlet shaft seal pump with negative pressure should keep the pressure in the stuffing box higher than the outside large vapor pressure. When the back pressure is reduced, the pressure of the stuffing box should be adjusted in time, otherwise the pump will suck the gas, causing the casting strip to break, affecting the pelletizing, and causing the pelletizer to release;

Fourth, the disintegration and cleaning of the anti-corrosion and wear-resistant pumps, raising and lowering the temperature, starting and stopping should be strictly controlled in accordance with the standards to reduce undue losses;

Fifth, in the application of anti-corrosion and wear-resistant pumps, always observe the running state, pay attention to temperature, noise, vibration and other conditions, and check and repair as soon as there are special conditions.

Sixth, the connection between the pump and the pipeline should maintain good air tightness, especially the water inlet pipe must ensure that there is no air leakage. Check current, voltage changes, and bearing temperature rise not higher than 75 degrees in time to prevent accidents.

Corrosion-resistant and wear-resistant pumps and anti-corrosion pumps are the key machinery in the chemical industry. They have a high demand for their precision, accuracy and safety performance, and the control personnel must have relevant skills to solve related faults.