Skype: +86 193 3849 2153

EMAIL: Nancy@jnhgbf.com

If you are interested in our products, Please get in contact with us .

E-mail: Nancy@jnhgbf.com Chat Line Send InquiryCharacteristics and Technical Parameters of Wear-resistant and Corrosion-resistant Slurry Pump

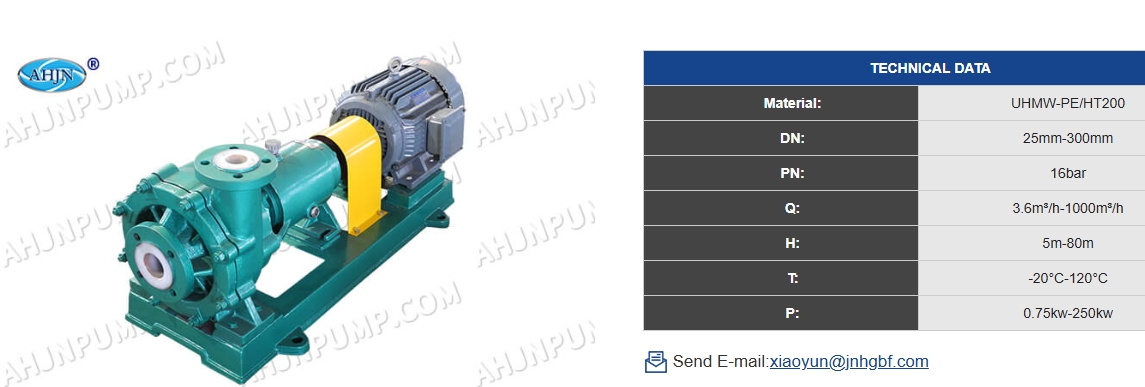

FMB-MODEL resistance to corrosion and abrasion pumps

The wear-resistant and corrosion-resistant slurry pump is a special type of pump designed to transport corrosive media containing fine particles, and it is widely used in various fields such as chemical, metallurgy, and environmental protection. This type of pump usually uses steel lining with ultra-high molecular weight polyethylene (UHMW-PE) as the material, due to its excellent wear resistance, impact resistance, and corrosion resistance, making it widely used.

Material Properties

The main material of the wear-resistant corrosion-resistant slurry pump, UHMW-PE, is a high-performance engineering plastic with excellent properties. Its wear resistance is the best among all plastics, 4 times that of nylon 66 (PA66) and PTFE, and 7-10 times that of carbon steel and stainless steel. In addition, UHMW-PE’s impact resistance is also excellent, and it can maintain stability in extreme low-temperature environments, even maintaining its performance at -196°C temperature.

Product Features

The design of the wear-resistant and corrosion-resistant slurry pump takes into account the characteristics of the medium and the harsh conditions of the use environment. The impeller design is semi-open, without a front cover plate, which increases the throughput in the flow channel, allowing the particles and impurities in the medium to pass through the pump chamber quickly without causing blockages. The sealing part uses a K-type fluorine rubber seal ring with a cooling water jacket, which not only meets the requirements of corrosion resistance but also satisfies the needs of wear resistance.

Application scope

The application range of the wear-resistant and corrosion-resistant slurry pump is very wide, and it can be used to convey a variety of corrosive media, such as slurries with a concentration of 80% or less of sulfuric acid, slurries with a concentration of 50% or less of nitric acid, hydrochloric acid and other acids, alkalis and salts. In the metallurgical industry, it can be used to convey various corrosive slurries; in the sulfuric acid industry, it is suitable for the conveyance of various dilute acids; and in the environmental protection industry, it can be used to convey various wastewater. In addition, due to its excellent wear resistance, it is also suitable for conveying highly abrasive materials in the coal and mining industries.

The main technical parameters of the wear-resistant and corrosion-resistant slurry pump include the temperature range for use (-20℃~90℃, in some cases up to 105℃), the inlet diameter (from 32mm to 350mm), the flow rate (5~600m³/h), and the head (up to 50m). These parameters ensure that the pump can maintain stable performance under different working conditions.

In conclusion, the wear-resistant and corrosion-resistant slurry pump with its unique material advantages and design features plays an important role in many industries. Its wide range of applications and high adaptability make it an indispensable important equipment in industrial processes. With the continuous advancement of technology, it is believed that the wear-resistant and corrosion-resistant slurry pump will show its value in more fields in the future.